3D-printing, and why you should join the profit trend now

Remember 3D-printing in the early years of 2020, when the COVID-19 virus was a significant threat. The world saw themselves searching for vital medical equipment, such as ventilators, face masks, and personal protective equipment, you name it.

China which is usually a significant source of these supplies, was occupied with COVID-19 issues of its own. Hospitals could not obtain these supplies.

Local businesses and tech-savvy designers were quick to offer assistance in whatever manner they could. Many of them included 3D-printing. 3D printers went into hyperdrive. In just a couple of weeks, the printing of tens of thousands of components was produced.

The pandemic revealed how fragile the global logistics chains could be. 3D-printing stepped in and took over the burden in dealing with these issues.

Nowadays, both nations and companies alike are still pondering their dependence on supply chains such as China. This could usher in the new age of 3D printing technology, which could disrupt the world's trading system forever.

There are different ways 3D-printing can alter our life. For you, Dear reader, this could mean opportunities to earn a profit. Let me demonstrate what I mean by that.

3D-printing is disrupting industries

A firm known as 3D Systems (DDD) used one of its 3D printers to print the Hammer. In retrospect, this was a revolutionary moment.

Ask a factory to build a single Hammer to the design of your choice. In the most reasonable of scenarios, if you do it right, you will end up with a bill of thousands of dollars (providing you don't get laughed out of the building).

The manufacturer must create a mold, mold the head, turn the handle with a wood handle, and assemble the components. This will result in a pricey tool.

If you're making thousands of hammers, every one of them will cost less due to the economics of scale. For a 3D printer, the economics of scale value is much less. It is possible to tweak its software infinitely, to create almost everything.

I mention this because it shows one aspect 3D-printing has been changing manufacturing. However, it's not the only one.

On account of the 21st Century, it is an industrial revolution

3D-printing is still cost-effective for small-scale production. The manufacturing process for high-scale 3D-printing is slow and costly compared to traditional production.

However, things are changing. Many businesses are employing 3D printing not just for prototypes but for production. Consider this: Why would you require massive warehouses to print any part you want upon demand?

Why would we require an industrial facility in China to manufacture parts for cars that are not necessary when we could 3D print this in America? Why would we have to cover shipping and transport charges for one-off items when we could 3D print the object on-site?

3D printing is not less than a new Industrial Revolution. Like it was during the Industrial Revolution that kicked off in the 18th Century, 3D printing will be a part of our lives, not only manufacturing.

Extraordinary 3D-printing applications

As I mentioned earlier, 3D-printing is altering the medical field and healthcare in more ways than one. Indeed, 3D printing is not just useful for medical equipment. It could also be utilized to produce components of the body. It could play an essential role in enhancing and saving people's lives.

The Wake Forest Institute for Regenerative Medicine is an example of its kind. It has developed methods to create human tissues using specialized 3D printers. It employs human cells as "ink ."

Thus, even though a typical 3D printer can use plastic to create an item, a bio-printer will layer organs and tissues. Scientists use cells from patients to make the body parts that are 3D printed to ensure that the body doesn't reject them.

They produce various functional body parts such as the ears, skin, valves, blood vessels, etc. Shortly, doctors could construct a kidney or a heart with the click of a button.

It's not a long time ago when early 3D printers could only print objects made of plastic. In the beginning, 3D printing was also expensive and was challenging to access; all this changed roughly in 2010 when; technological advancements enabled 3D printers to be more affordable, putting them in the hands of consumers.

The 3D-printing technology is expected to be even more appealing soon. For instance, advanced artificial intelligence (A.I.), discussed in previous articles - will accelerate 3D printing. A.I. can enable 3D printing to be more efficient and require less human input.

The 3D-printing will be even quicker and more affordable in the coming years. If this occurs, 3D-printing will unleash an incredible revolution. As mentioned previously, there is a potential profit angle when technological advances occur.

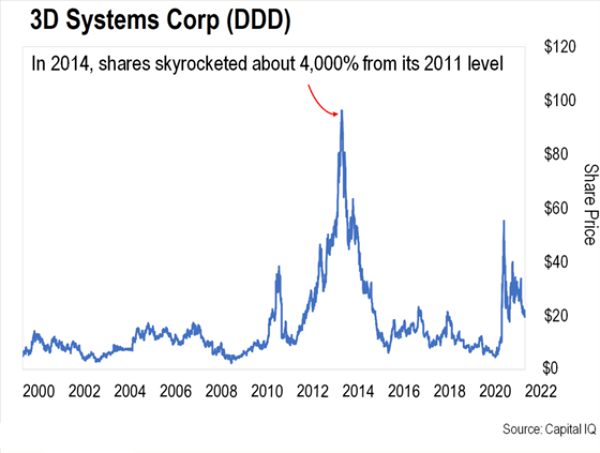

You might remember the initial 3D printing boom in 2013/2014. The share price of 3D printing companies skyrocketed. Below is a chart that shows 3D Systems - the company which produced the hammer I talked about at the top. It's currently the largest 3D printing company in the world.

As you see in the chart, 3D Systems's shares increased by nearly 4,000% during the boom in 3D printing back into 2014. The boom then became a bust as the initial 3D-printers did not perform as promised. The shares of many companies plummeted more than 80 %.

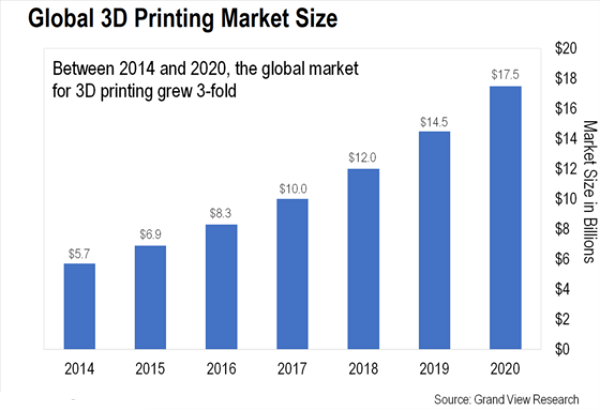

However, that doesn't necessarily mean that 3D printing was over - certainly not. Take a look at the following chart. It shows how the market for 3D-printing has grown since 2014.

It is an unmistakable rebound of the global 3D printing market that has tripled its value since 2014. Yet, 3D printer stocks are still down 80% from their peak from 2014. This illustrates the gap discovered between the market and the actual economy.

As the 3D printing market makes impressive progress, however, the stock market has left it in a ruined state. Soon, however, the market will catch up.

Many large institutions and businesses have already begun employing 3D printing to be more efficient. This comprises Nike, General Electric, the Audi, United Parcel Service (UPS), and even the United States Navy.

Most notably, the growth in the market for 3D printing is expected to keep growing and expanding. According to market research firm Grand View Research, the 3D-printing market globally could be worth $63 billion in 2028. This represents an increase of 3.6 times from the current level.

How to join in on this revolutionary new trend

In 2013 and 2014, the hype outweighed the actual technology, as the examples above illustrate that the opposite is true. 3D-printing's megatrend transforms many industries and creates the economic value worth billions.

It is just a matter of time before the market gets it. If it does, I'm expecting the gains of a few 3D printing stocks to be just as impressive as those that exploded during the previous eruption.

Unfortunately, you are not likely to see the majority of these opportunities currently except if you're willing to invest your hard-earned money into tiny 3D-printing players that are not well-known.

They tend to be volatile. They typically come with the risk of best suited to people with an affinity for the more high-risk table.

The good news is that there's an alternative (safer) method to make the most of this opportunity. The ETF for 3D printing (PRNT) can be described as a simple 3D printing investment you can open using an account with your brokerage firm.

PRNT is home to around $394 million in assets under management. Also holds 54 stock holdings, including 3D-printer manufacturer Desktop Metal (D.M.) and H.P. (HPQ), the top technology company in America.

The fund provides an easy method to place bets on companies engaged in 3D-printing.

This article was printed from TradingSig.com